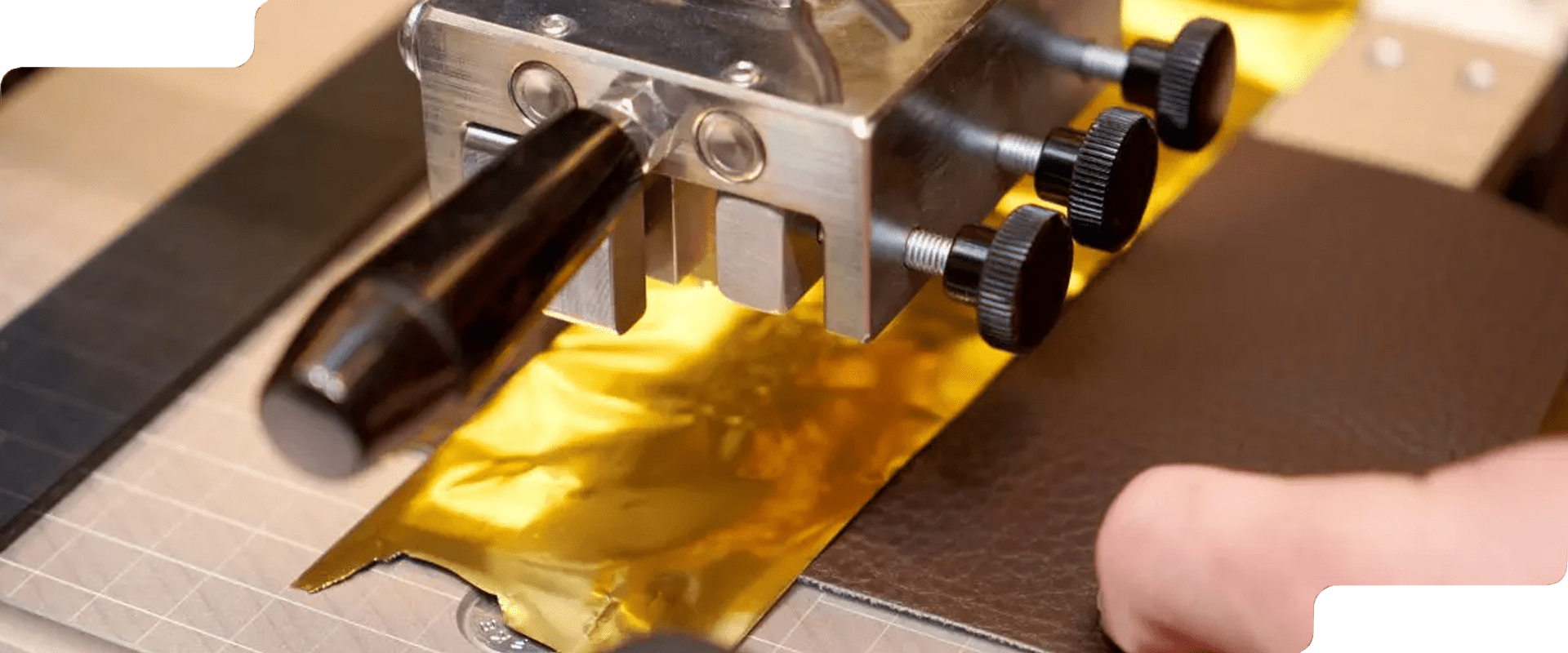

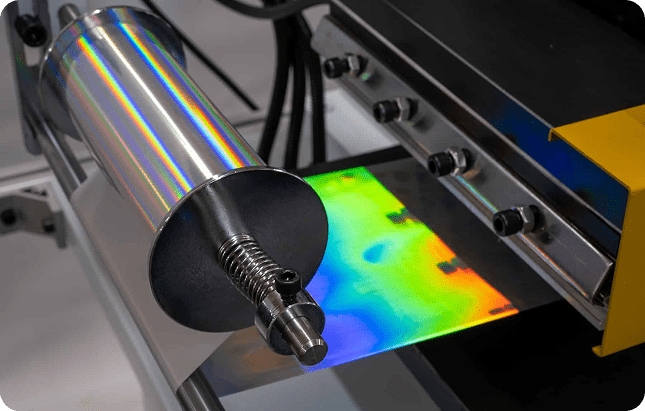

Hot stamping, also known as foiling, is a decorative printing process where metallic or pigmented foils are applied to a substrate using heat and pressure. This technique creates a high-quality, reflective finish, enhancing the aesthetic appeal of products. It is commonly used for branding, logos, and intricate designs on a variety of materials, including plastic, paper, and leather. Hot stamping offers a premium, professional look and is ideal for products requiring a durable and visually striking finish.

We specialize in contract component manufacturing for plastic parts

In essence, hot foil stamping involves the use of heat and pressure to transfer metallic foil or holograms onto materials like light papers, carton board, laminated board, plastics, and corrugated board. The term "hot foil stamping" covers processes such as simple flat foil stamping.

Hot foiling, or hot foil stamping, is a process that uses heat and pressure to transfer metallic or pigmented foil onto materials like paper, plastic, and cardboard. It creates a shiny, reflective finish, often used for branding and decorative designs.

Hot foiling uses heat and pressure to apply foil, creating premium finishes. Cold foiling uses adhesive and UV light or heat, offering faster production and flexibility.

Hot stamping is a printing process where heated dies transfer metal foils or pre-dried inks onto a surface. The die presses the foil onto the material, creating a metallic or colored design.

Contact us for custom, bulk, or high-precision plastic components that meet your industry needs.

Copyright © 2025 Maniar Plast. All rights reserved.

Powered by Augment Works.

WhatsApp us