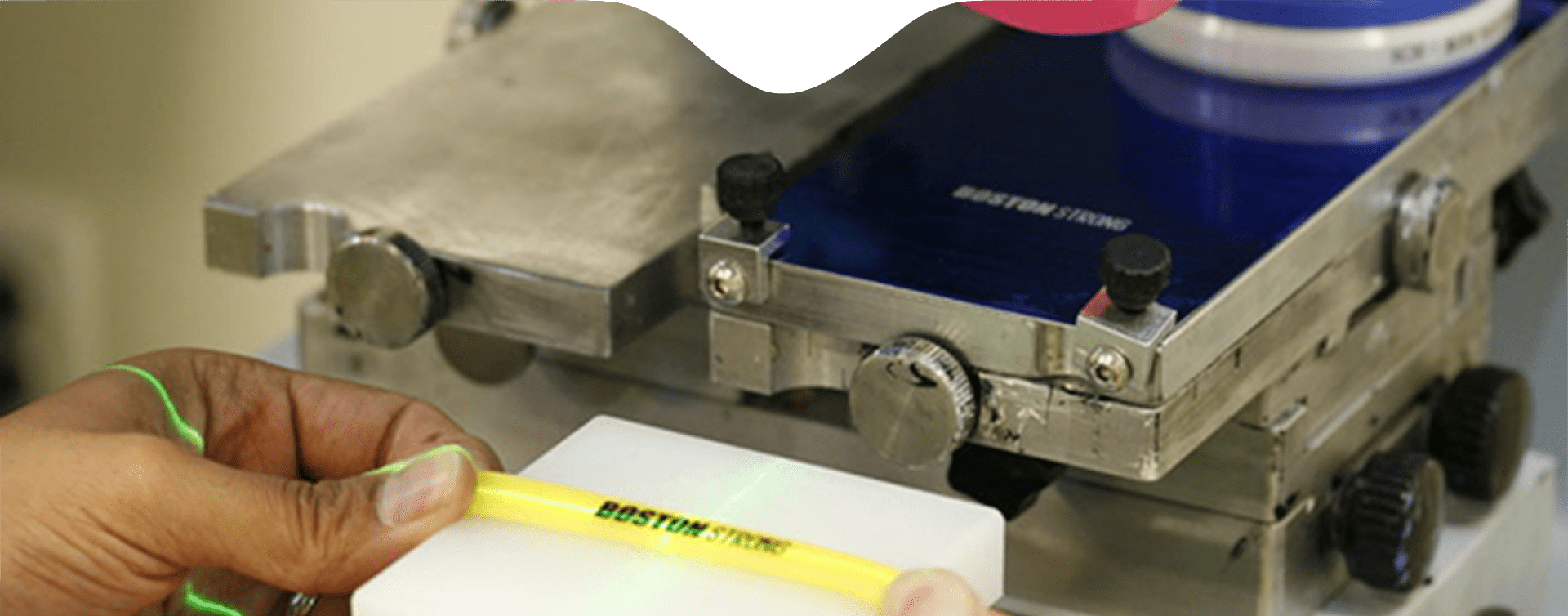

Pad printing and automatic screen printing are advanced techniques used to transfer high-quality designs onto plastic and other materials. Pad printing allows for precise printing on uneven surfaces, ideal for small, intricate designs. This method is widely used in industries such as medical device components, consumer electronics, and automotive parts.

We specialize in contract component manufacturing for plastic parts

Choosing the right printing method depends on the project. Screen printing is ideal for large images on t-shirts, while pad printing is better for small, uneven, or curved surfaces and capturing fine details.

An automatic screen printer ensures consistent quality across batches, with no variation between products. It also reduces the need for manual labor, as the machine handles most of the work.

Spot Color Screen Printing is the most common t-shirt printing method. Other methods include Halftone Printing (gradients), Grayscale Printing, Duotone Printing, CMYK Printing, and Simulated Process Printing.

Automatic printing is ideal for systems like conveyors, where components are processed in order. Labels can be attached to provide key production details, such as order numbers or SFC.

Screen printing, also known as silk screen printing, is a custom printing method where ink is transferred onto a substrate using mesh. It’s a stencil technique where a design is imposed on a screen, and the blank areas are coated to block the ink.

Contact us for custom, bulk, or high-precision plastic components that meet your industry needs.

Copyright © 2025 Maniar Plast. All rights reserved.

Powered by Augment Works.

WhatsApp us